Views: 0 Author: Site Editor Publish Time: 2025-10-02 Origin: Site

A SILAGE FILM MACHINE helps keep animal feed fresh and safe. You use it to wrap chopped plants very tightly. This keeps out air and moisture. The tight seal protects your silage from rain and bugs. It also stops spoilage.

Studies show high oxygen barrier films cut waste in the top silage layers by 42%. They also make feed better by lowering butyric acid levels.

When you use these machines, your animals get better food. Their food stays the same quality for longer. Your farm work gets easier and faster.

A SILAGE FILM MACHINE helps turn fresh crops into good silage. There are a few steps in the process. Each step keeps animal feed safe and healthy.

First, you harvest crops like corn or cereals. You pick them when they are green and full of nutrients. Move the crops quickly to the silo. This keeps them fresh for the next step.

Then, you chop the crops into small pieces. Most machines cut them into 2 to 5 centimeter sections. Chopping makes it easier to pack the silage tightly. It also helps animals eat the feed.

After chopping, you compact the silage with the SILAGE FILM MACHINE. Compaction pushes out air from the pile. This step is important because it removes oxygen. Without air, bad bacteria cannot grow. This keeps your silage from going bad.

Last, you seal the silage with a special film. The SILAGE FILM MACHINE wraps the pile with plastic film. The film blocks air and water. You can use tires, sandbags, or gravel to hold the film down. This makes the seal tighter.

Tip: Always pick strong, oxygen-barrier silage films. A tight seal keeps silage fresh and safe for months.

A SILAGE FILM MACHINE makes work faster and easier. You save time and make fewer mistakes. Machines chop crops evenly and compact them better than doing it by hand. You get silage that is more even, which helps fermentation.

Here is a table that shows how silage film machines help you work better:

| Feature | Benefit |

|---|---|

| Automation | You spend less on workers and avoid mistakes. |

| Precision Chopping | Crops are cut evenly, which helps fermentation. |

| Roller Compression | Air is pushed out, so silage gets better. |

| Moisture Sensors | Machines keep moisture just right for silage. |

| Inoculant Sprayers | Fermentation starts faster, making better feed. |

| Hydraulically Powered Intake | You avoid blockages and waste less. |

| Silage Balers | Forage is wrapped tightly for long storage. |

| Self-Propelled Harvesters | You do many steps at once, saving time. |

| GPS and Auto-Steering Systems | You cover fields better and save resources. |

| Corrosion-Resistant Materials | Machines last longer and need less fixing. |

Airtight sealing is very important. When you use a SILAGE FILM MACHINE, you keep out air. This makes anaerobic conditions. Lactic acid fermentation starts. This keeps nutrients in your silage and stops spoilage. Your animals get healthy food all year.

A SILAGE FILM MACHINE has many parts. Each part does a special job. When you know how these parts work, you can keep animal feed fresh.

The chopper cuts crops into small pieces. You can pick how long you want the pieces. Shorter pieces pack better and ferment faster. Some machines let you change the knife settings. You can pick how many knives to use. You can also change the chop length. This helps you control how your silage feels.

| Chopper Unit Type | Chop Length (mm) | Knife Options |

|---|---|---|

| 15 Knife Chopper | Approximately 65 | Standard Unit |

| Selectable Knives | Variable | Engage/Disengage Both Knife Banks |

Tip: Pick the right chop length for your animals. Shorter pieces help cows eat more and digest food better.

The compactor presses the chopped crops tightly. You want to get rid of as much air as you can. This step is very important. Packing well stops spoilage and helps good bacteria grow. The compactor helps you get the right density. You can stop oxygen pockets and keep nutrients in your silage.

The compactor removes oxygen fast.

Good packing stops spoilage germs.

Fast anaerobic conditions help fermentation.

Packing shrinks oxygen pockets.

Good density turns carbs into acids and carbon dioxide. This keeps silage stable.

Note: If you pack silage loosely, you can lose nutrients and get mold.

The film applicator wraps the packed silage with plastic film. This film keeps out air, water, and sunlight. You can pick films that are strong and hard to tear. Some films block UV rays and let little oxygen in. These things protect your silage from damage and spoilage.

Strong film does not tear easily.

Puncture resistance keeps silage safe when you move it.

UV resistance stops sunlight from hurting the film.

Low oxygen permeability keeps silage fresh.

High moisture vapor transmission rate helps remove extra moisture.

Modern film applicators use automatic systems. You can set the machine to cut and change reels without stopping. This saves time and lowers mistakes.

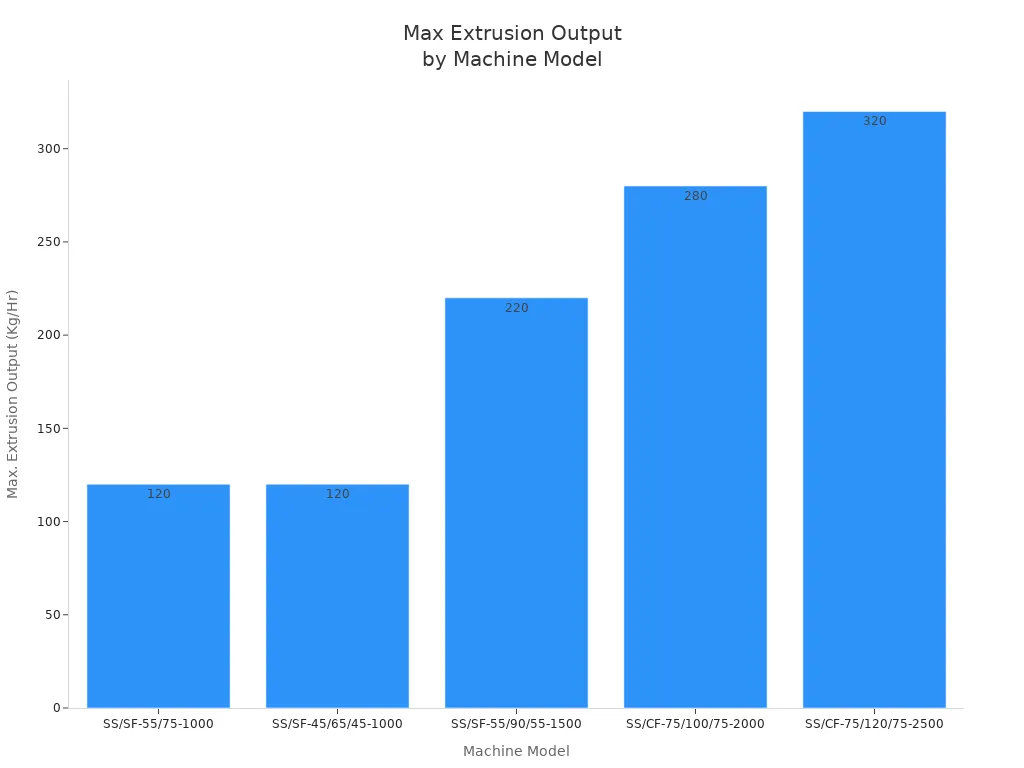

| Model | Material | Screw Size (MM) | Film Width (MM) | T-Die Width (MM) | Max. Extrusion Output (Kg/Hr) | Winder | Machine Dimension (Mtrs) (L x W x H) |

|---|---|---|---|---|---|---|---|

| SS/SF-55/75-1000 | LLD/LD/PIB | 55/75 | 1000 (Finished) | 1250 | 120 | Surface Roll Winder with Auto Cutting & Reel Changeover System by PLC | 12 x 4 x 5 |

| SS/SF-45/65/45-1000 | LLD/LD/PIB | 45/65/45 | 1000 (Finished) | 1250 | 120 | Surface Roll Winder with Auto Cutting & Reel Changeover System by PLC | 15 x 5 x 5.5 |

| SS/SF-55/90/55-1500 | LLD/LD/PIB | 55/90/55 | 1500 (Finished) | 2300 | 150-220 | Surface Roll Winder with Auto Cutting & Reel Changeover System by PLC | 17 x 6 x 6 |

| SS/CF-75/100/75-2000 | LLD/LD/PIB | 75/100/75 | 2000 (Finished) | 2800 | 150-280 | Surface Roll Winder with Auto Cutting & Reel Changeover System by PLC | 19 x 7 x 6.5 |

| SS/CF-75/120/75-2500 | LLD/LD/PIB | 75/120/75 | 2000 (Finished) | 2800 | 200-320 | Surface Roll Winder with Auto Cutting & Reel Changeover System by PLC | 22 x 8 x 6.5 |

Machines with higher extrusion output wrap more silage faster. You can pick a model that fits your farm size and needs.

Modern technology has changed how you use a SILAGE FILM MACHINE. Today, smart features help you make better silage with less work. These machines use sensors and control panels. Automation gives you more control and better results.

Sensors are important for making silage. They check things like bale density, moisture, and temperature. You get real-time data from sensors. This helps you make quick choices. Sensors measure how tightly you pack each bale. This keeps the right density. Good density makes feed better and cuts waste.

Here is how sensors help you:

| Mechanism | Contribution to Process Optimization and Feed Quality |

|---|---|

| Monitoring bale density | Pressure sensors help you get the best bale density. Productivity goes up by 14%. |

| Control of ensilage additives | Additives are spread evenly. Sensors check moisture and pressure. This makes forage better. |

| Real-time data utilization | Dosing agents is automatic. You make better choices and lower spoilage risks. |

Smart sensors also check temperature and moisture. These sensors help you find problems early. You can fix issues before silage goes bad.

The control panel helps you run the machine. You use it to start, stop, and change the wrapping. Some panels have levers. Others use touch screens or joysticks. Many machines have computer controls. This makes your job easier.

Here are some features you might find on a control panel:

| Function/Feature | Description |

|---|---|

| Manual Control System | Cable levers let you control the machine. You get a bale-and-wrap counter and auto-stop. |

| Bale-and-Wrap Counter | Counts film layers and wrapped bales. |

| Auto-Stop Function | Stops wrapping when the right number of layers is reached. |

| Computer-Controlled Version | A control box lets you wrap bales automatically. You use a joystick for many functions. |

| Remote-Control System | Some wrappers let you control them from far away. This gives you more freedom. |

| ISOBUS Compatibility | Sensors and control systems talk to each other. This makes automation better. |

Pick a control panel that fits your needs. Some panels let you control the machine from far away. This gives you more choices on the farm.

Automation makes work faster and more reliable. Automated systems wrap bales with the right amount of film. This lowers mistakes and keeps silage safe.

Here are some ways automation helps you:

Airtight seals keep silage fresh and full of nutrients.

The machine works without stopping. You wrap more bales in less time.

Film is put on evenly. Every bale gets the same protection.

New machines use data analytics and IoT to check silage quality in real time. Some use machine learning to help you make better choices. You can get models with up to 7-layer co-extruded film. Some films have UV protection and special resins for tough weather. These features give you better results and peace of mind.

Tip: Pick machines with smart features like remote monitoring, automatic dosing, and strong film. These upgrades save time and make silage better.

You want your animals to eat healthy food. Using a SILAGE FILM MACHINE helps keep nutrients in silage. The machine wraps feed tightly and blocks air. This keeps nutrients from escaping and keeps silage fresh.

Many farmers get better results with oxygen barrier films. These films keep dry matter and nutrients inside silage. You get feed with more energy and protein. Your animals eat better and stay healthy.

Oxygen barrier films lower dry matter loss.

More vitamins and minerals stay in silage.

Fermentation works well, so feed tastes and smells good.

Animals get silage with better nutrition.

If you want healthier animals, keep nutrients in their feed. A tight seal helps a lot.

Spoilage can ruin silage and waste your work. You can stop spoilage by using the right machine and good steps. The SILAGE FILM MACHINE wraps bales with the right tension and overlap. This keeps out air and water, stopping mold and rot.

Check crop moisture before wrapping. Aim for 40-60% moisture. This helps silage ferment well and stops spoilage. Packing silage tightly is important. Try for a bale density of 14-18% dry matter. This makes an oxygen-free space for good bacteria.

Right moisture keeps silage fresh.

Tight packing stops air pockets and mold.

Regular machine care stops breakdowns.

Good film tension and overlap block moisture and pests.

Following these steps protects feed and saves money. You make sure animals get safe food every day.

You need to keep silage safe from rain, hail, and bugs. The SILAGE FILM MACHINE gives a strong seal that blocks these threats. You can store silage almost anywhere, even on dry ground. This helps you use land better and avoid muddy spots.

A tight seal also stops nutrients from washing away. You keep more feed and waste less. The film blocks bacteria, yeasts, and molds. Your silage stays safe and clean.

| Advantage | Environmental Factor Mitigated |

|---|---|

| Good preservation with less nutrient loss | Cuts spoilage from yeasts, molds, and bacteria, keeping nutrients |

| Flexible storage location | Lets you store on dry ground, lowering land impact |

| Complete sealing of silage | Stops nutrient loss through runoff, making feed better and cutting waste |

You help the environment by wasting less and using resources well. Your farm stays cleaner, and animals get better feed.

You want to make sure your animals get enough food every day. Feed budgeting helps you plan how much silage you need for your herd. Silage film machines make this job easier and more accurate. When you use these machines, you keep your silage fresh and safe. You lose less feed to spoilage or waste. This means you can count on your silage supply all year.

Silage film machines wrap and seal your feed tightly. You get better preservation and higher quality silage. Your animals eat food with more nutrients. You spend less money on extra feed because you waste less. You can plan your feed use with confidence.

Tip: Track your silage inventory after each harvest. Use the data from your silage film machine to adjust your feed plan.

Farmers around the world now use high-speed baling and wrapping equipment. These machines need films with strong and consistent quality. You get faster silage production and lower labor costs. You save time and money. You can focus on other important jobs on your farm.

Here is how silage film machines help you with feed budgeting:

You reduce feed waste by keeping silage fresh.

You improve feed quality, so animals need less extra nutrition.

You lower costs by using less labor and fewer additives.

You plan your feed supply for each season with more accuracy.

You can use a simple table to track your feed budgeting:

| Month | Silage Used (tons) | Silage Remaining (tons) | Feed Waste (tons) | Notes |

|---|---|---|---|---|

| January | 12 | 88 | 1 | Cold weather, low waste |

| February | 15 | 73 | 2 | Increased feeding |

| March | 10 | 63 | 1 | Stable conditions |

| April | 13 | 50 | 1 | Rainy, good seal |

You can update this table every month. This helps you see how much silage you use and how much you have left. You spot problems early and fix them before you run out of feed.

Silage film machines also help you apply additives evenly. You can add nutrients or preservatives during wrapping. This makes your silage last longer and keeps animals healthy. You control the quality of every bale.

Note: Good feed budgeting means you never run short. You keep your animals healthy and your farm running smoothly.

When you use silage film machines, you get more control over your feed supply. You make better choices for your animals and your business. You save money, reduce waste, and improve your farm’s efficiency. Feed budgeting becomes simple and reliable.

Using a silage film machine saves you lots of time. The machine does jobs that take hours by hand. You do not need a big team to chop and wrap silage. The machine does these steps fast and makes fewer mistakes. You can do other important jobs on your farm.

Many machines work automatically. You press a button to start chopping and wrapping. You do not need to watch every step. Sensors check moisture and density for you. You get the same results each time. You spend less time fixing problems. Your team can feed animals or fix equipment.

Tip: Pick machines with remote controls. You can use them from far away and save even more time.

Silage film machines help you spend less money. You lose less feed because the film keeps out air and water. You do not need to buy extra feed if silage spoils. The film is strong and does not break easily. You spend less on repairs and new film.

Machines also lower labor costs. You do not need extra workers at harvest time. The machine works faster than people. You get better silage, so animals stay healthy. You spend less on extra food for them.

Here is a table that shows how silage film machines help you save money:

| Key Benefit | Description |

|---|---|

| Reduced Feed Spoilage | Advanced film technology minimizes spoilage, leading to less waste and better quality silage. |

| Enhanced Durability | Improved film durability results in less breakage during handling, ensuring more effective storage. |

| Increased Efficiency | Mechanized baling and wrapping improve operational efficiency, reducing labor costs for farmers. |

| Better Nutritional Content | Quality films help maintain the nutritional value of silage over extended storage periods. |

| Economic Gains | Overall, these factors contribute to improved economic yields for farmers due to reduced losses. |

You keep more of your crops. You spend less on workers and repairs. You get more value from your silage.

A silage film machine helps you use your time better. The machine works fast and does not need much watching. You finish making silage quickly. You can plan your day and do more jobs.

You do not need perfect weather to wrap silage. The machine wraps silage tightly, so rain or wind does not ruin it. You can store silage right after harvest. You do not need to hurry or worry about delays.

You finish wrapping silage faster.

You do not have long breaks between steps.

You can plan feeding and fixing equipment more easily.

Note: Good time management helps your farm run smoothly. You get more done and feel less stress when you are busy.

Silage film machines help you control your workday. You save time, spend less money, and keep your feed safe. Your farm works better, and your animals stay healthy.

Picking the right silage film machine helps your farm every day. You should choose a machine that matches your farm’s size. Make sure the machine works with your other equipment. This helps you use it easily. Think about these things when you pick a silage film machine:

If your equipment fits together, you save money.

A good price means you get more for your money.

Your farm’s size tells you what machine you need. Big farms need machines that work faster.

Many film sizes and thicknesses give you choices.

Good suppliers give you strong machines and films.

You can talk to suppliers for help. They know which machines fit small or big farms. Small farms may need smaller machines. Large farms often need stronger and faster machines.

Tip: Always look at the warranty and support before you buy. Good support helps you fix problems fast.

Taking care of your silage film machine keeps it working well. You protect your money and keep silage fresh. Follow these steps for best results:

Pack corn over 240 kg DM/m³ and grass over 200 kg DM/m³. This pushes out air and helps fermentation.

Seal the silo right after packing. Fast sealing keeps oxygen out.

Use an oxygen barrier underlay film and a tough top film. Two layers protect better.

Pick strong EVOH barrier films. These films block oxygen and keep silage safe.

Try 2-in-1 combi rolls. They make covering silage quick and easy.

Use strong nets to protect the silo from animals and weather.

Hold the film down with gravel bags. Gravel bags spread weight and keep the seal tight.

Check for holes or tears often. Fix or replace damaged spots right away.

Plan how to take off the cover when feeding. Careful removal keeps silage clean.

Doing these steps keeps your machine working well. Your silage stays fresh and safe for animals.

Note: Clean your machine after each use. Dirt and crop bits can cause trouble later.

You can make your farm work better by linking your silage film machine with other tools. Many machines work with balers, choppers, and loaders. You save time when you connect these machines.

A simple table helps you plan how to link equipment:

| Equipment Type | Integration Benefit | Example Use Case |

|---|---|---|

| Baler | Faster wrapping | Bale and wrap in one step |

| Loader | Easier transport | Move silage quickly |

| Moisture Sensor | Better feed quality | Adjust wrapping settings |

You can connect your silage film machine to a control panel or remote system. This lets you change settings from anywhere on your farm. You get more control and better results.

Tip: Teach your team how to use linked systems. Good training helps everyone work safely and quickly.

Silage film materials are changing a lot now. Makers use multi-layer designs to make films stronger. These layers block oxygen and keep silage fresh longer. Some films, like Silostop Max, have up to 11 layers. They are 80 microns thick. This design stops oxygen from getting in. It also lowers dry matter loss at the top. Your silage stays good and you waste less feed.

New silage films have special additives. UV stabilizers protect the film from sunlight. Anti-puncture additives make the film tough. The film does not tear easily outside. Many farmers pick biodegradable and compostable films now. These choices help you protect the environment and keep silage safe.

Multi-layer films block oxygen better.

UV stabilizers help films last in sunlight.

Anti-puncture additives stop tears when handling.

Biodegradable and compostable films help the earth.

Tip: Pick silage films with strong oxygen barriers and UV protection. This gives you good results in any weather.

Silage film machines have smart features that help you. You can use sensors to check inside each bale. Sensors measure oxygen, temperature, and moisture. You get data right away. This tells you when silage needs care. QR codes on bales help you track each one. Scan the code to see storage details. This helps you stop spoilage.

Automated baling and wrapping machines use special films. These machines wrap bales fast and evenly. You save time and need fewer workers. Smart features let you control the process. They help you make better silage.

Sensors check bale conditions to keep silage fresh.

QR codes give you storage and tracking info.

Automated machines work faster and need less labor.

Block Quote: Smart technology keeps silage safe. It makes your work quicker and more reliable.

You help the earth when you use sustainable silage film machines. Makers now follow rules to lower plastic waste. The U.S. makes lots of farm plastic. New laws push companies to find better ways. More biodegradable silage films are sold now. These films break down on their own and meet green standards.

Sustainable choices match what people want. You pick products that protect land and animals. Using eco-friendly films helps farms stay clean. It gives your animals healthier food.

| Sustainable Practice | Benefit for You and the Environment |

|---|---|

| Biodegradable films | Less plastic waste, easier disposal |

| Compostable materials | Improve soil health after use |

| Regulatory compliance | Meet new standards, avoid penalties |

Note: Using sustainable silage films helps your farm and the planet.

You use silage film machines to help with your feed. First, you harvest the crops. Next, you chop them into small pieces. Then, you compact the feed to push out air. Last, you seal it tight with film. This keeps good things in and stops waste. The table below shows how these machines help your farm:

| Benefit | Description |

|---|---|

| Nutrient Retention | Silage wrap keeps nutrition high for your animals. |

| Waste Reduction | Airtight covering cuts spoilage and feed loss. |

| Cost Efficiency | Well-preserved silage lowers your need for extra fodder. |

| Year-Round Feed Availability | You get steady, high-quality feed even when fresh crops are gone. |

New technology gives you smart packaging and films that break down. You can check your silage in real time. Your feed gets stronger protection. These new features help your farm work better and protect the earth.

A silage film machine wraps chopped crops tightly with plastic film. You keep air and water out. This helps you protect animal feed and stop spoilage.

You should clean your machine after every use. Dirt and crop bits can cause problems. Regular cleaning helps your machine last longer and keeps silage fresh.

You should use special silage films. These films block oxygen and resist tearing. Regular plastic does not protect feed well. Pick films made for silage to get the best results.

Sensors check moisture, temperature, and bale density. You get real-time data. This helps you adjust settings and keep silage safe and nutritious.

If you leave gaps, air gets in. Mold and bad bacteria grow. You lose nutrients and feed quality drops. Always seal silage tightly to keep it safe.

Yes! You lose less feed to spoilage. You spend less on labor and repairs. Your animals eat better, so you buy less extra feed. Silage film machines help you run your farm efficiently.

You can use silage film machines on any farm size. Small machines work well for small farms. You get the same benefits—fresh feed, less waste, and easier work.

Tip: Always check your machine’s manual for best practices. This helps you get the most out of your silage film machine.